Cart

Discount: 0.00 CZK

Discount: 0.00 CZK

Digital Skipper |16/04, 2024

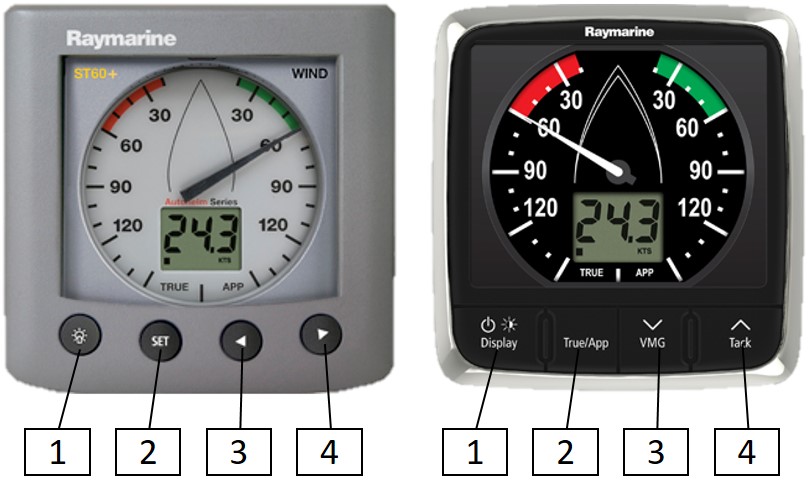

If your instruments display the same data type (e.g., both set to apparent wind or both to true wind) from the same source sensor, but still show different angles, the problem is usually due to pointer calibration in the analog display. This is not the same as standard calibration for wind, rudder, or compass angle, but a low-level factory/self-test calibration not documented in the manual.

The discrepancy arises when the display believes the pointer is showing a certain angle, but the pointer physically points to another. This was a common problem with ST60 and ST60+ and sometimes occurs on i60 as well.

It is almost impossible for one display to send a correct wind angle and another to receive it incorrectly – the network has error checks that prevent this. If you see a deviation, it is almost always due to the pointer's calibration, not the sensor data.

You need to perform a self-test procedure to calibrate the pointer's position. During the procedure, you cycle the display through angles in 30° increments and adjust the pointer to match the LCD value. Do three rounds: adjustment, fine-tuning, and verification.